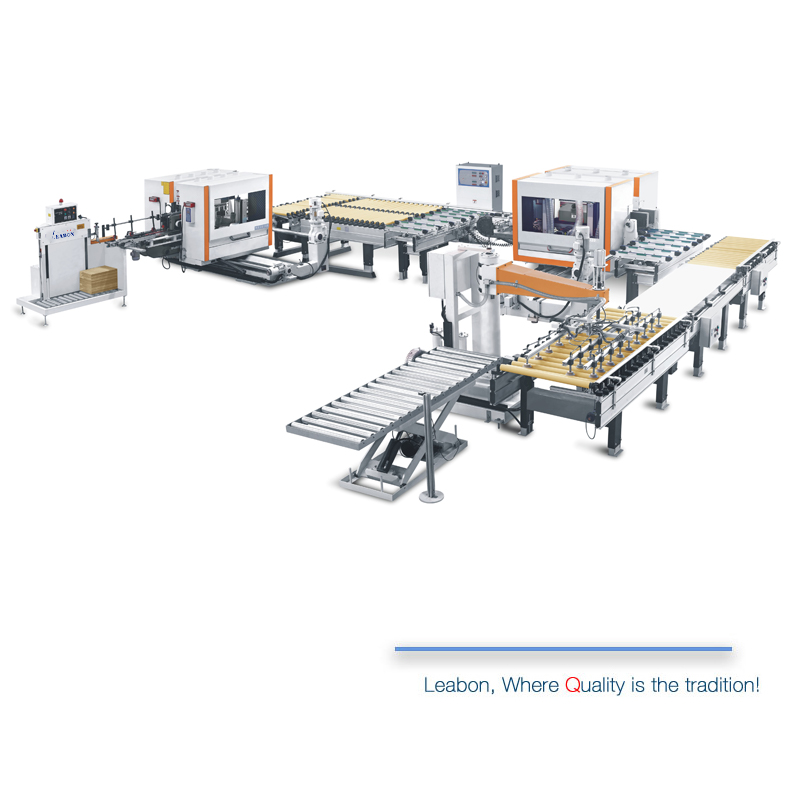

Introduction:CNC Compound Machining Center! This machine packs a powerful punch with its advanced one-time clamping feature, multi-process processing capabilities, and cutting-edge molding technology. With its modular programming system, this machining center is easy to operate and simple to set up, making it the perfect choice for both seasoned professionals and newcomers to the industry alike. Our design team has also ensured that this machine boasts a sturdy and durable construction, a beautiful appearance, and high-quality performance - in short, you can count on this machine to last you a lifetime. One of the standout features of the CNC Compound Machining Center is its heavy-duty mechanism that delivers incredibly accurate and stable precision, no matter what project you are working on. Whether you're working on chair legs, mortise and tenon processing, or another short material product, this machining center is up to the task. And with its optional protective cover, you can rest assured that your project is not only accurate but safe and clean, with excellent dustproofing capabilities. In conclusion, our CNC Compound Machining Center is a versatile and reliable addition to any manufacturing facility, whether you're working in furniture, woodworking, or any other industry that requires precision, accuracy, and durability. With its cutting-edge features, user-friendly programming, and robust design, it is sure to be a valuable tool for your business for years to come.

Introduction:CNC Compound Machining Center! This machine packs a powerful punch with its advanced one-time clamping feature, multi-process processing capabilities, and cutting-edge molding technology. With its modular programming system, this machining center is easy to operate and simple to set up, making it the perfect choice for both seasoned professionals and newcomers to the industry alike. Our design team has also ensured that this machine boasts a sturdy and durable construction, a beautiful appearance, and high-quality performance - in short, you can count on this machine to last you a lifetime. One of the standout features of the CNC Compound Machining Center is its heavy-duty mechanism that delivers incredibly accurate and stable precision, no matter what project you are working on. Whether you're working on chair legs, mortise and tenon processing, or another short material product, this machining center is up to the task. And with its optional protective cover, you can rest assured that your project is not only accurate but safe and clean, with excellent dustproofing capabilities. In conclusion, our CNC Compound Machining Center is a versatile and reliable addition to any manufacturing facility, whether you're working in furniture, woodworking, or any other industry that requires precision, accuracy, and durability. With its cutting-edge features, user-friendly programming, and robust design, it is sure to be a valuable tool for your business for years to come.Adopt special tenon and mortise modular control system. Easy to operate, modular editing.

The tool magazine is designed to be 90°, cross-arranged, processed by precision CNC, and the accuracy is within ±0.02mm.

Adopt international brand French Schneider Electric.

All line rail slider screw oiling is controlled by microcomputer. Automatic timing and quantitative oil injection. Ensure that each slider and each set of screw rods can be fully lubricated to improve the stability and service life of the equipment.

The special cooling high-pressure fan is used to run synchronously with the high-speed motor to achieve the best cooling effect and improve the service life of the motor.

All control lines of the equipment adopt flexible shielded lines, which are anti-interference and have a long service life to ensure stable operation of the equipment without interference.